Services

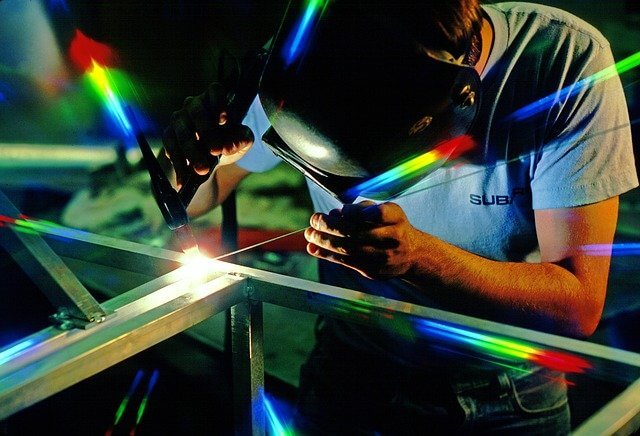

Welding Engineering Consultancy

- We specialize in problem solving related to welding of stainless steels, low alloy steels, carbon steels, hardfacing, and welding of dissimilar metals.

- Selection of welding electrodes, Filler Metal, and Consumables for the given combination of metals.

- Feasibility Study on Weldability, Application of filler metal for dissimilar metal welding.

- Providing viable technical solutions to the problems relevant to the Weldability of dissimilar metals

- Analyzing the Welding Metallurgical problem in-depth and providing feasible solutions with supporting documents.

- Root Cause Analysis of Welding Failure

- Weld Repair Procedure

- Expert advice in Welding of Stainless Steels and Nickel-based alloys.

- Solutions for fabricated Metal surface finishing & treatments ( Picking & Passivation)

Welding Engineering Education & Training for Skill development

- Education on Engineering materials and their selection for the given application.

- Arc Welding Processes –SMAW GTAW, PAW, GMAW & SAW.

- Destructive Testing of Welded joints & Acceptance Criteria as per ASME / ISO / API Code.

- Assessment of Weldability & Weldability Test and quantification

- Welding Metallurgy of Carbon Steel, Low Alloy Steel, Stainless Steel, Nickel, Aluminum, Titanium based alloys.

- Dissimilar Metal Joining Techniques.

- Welding Procedure Specification (WPS), Procedure Qualification Record (PQR), and Welder Performace qualification (WPQ) as per ASME / EN/ ISO standards.

- Awareness & Understanding on ISO 3834 ( Welding Quality management system).

- Support for EN Certification(EN ISO 3834, EN 15085, EN 1090 Etc.)

- External Responsible Welding Coordinators (RWC-IWE) Services.

- Skill development Training programs for Welders.

- Safety Practices in Welding.

Professional Training in Non Destructive Testing (NDT)

- ASNT Level II & Level –III Certification Programs

- Visual Testing (VT)

- Magnetic Particle Testing (MPT)

- Liquid Penetrant Testing(LPT)

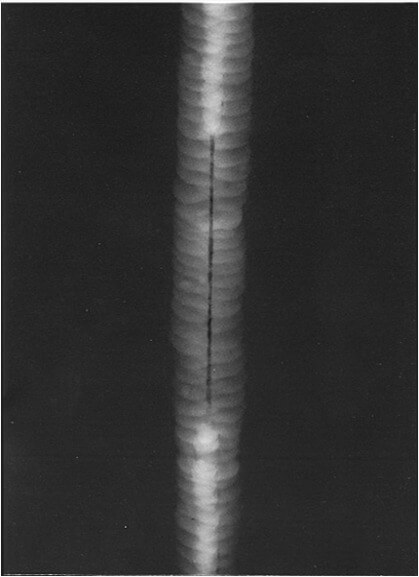

- Radiographic Testing (RT)