17-4 PH (S17400) is classified under ASTM A693 Type 630 is Chromium-Nickel-Copper precipitation hardening Stainless Steel used for applications requiring high strength and a moderate level of corrosion resistance. High strength is maintained to approximately 600°F (316°C). Which require heat treatment from the Condition A (mill annealed soft condition). In 17-4PH, Condition A is brought by annealing at approximately, 1060 °C followed by air cooling to room temperature. The 17-4PH is supplied from Steel mill in Condition A. The welding of 17-4PH is started with Condition A, although it has martensitic structure it can be successfully welded, It is because the of the very low Carbon ( 0.04 Wt-%) Martensite. Then after welding, to take the benefit of the strength of this precipitation hardening grade steel , it is subjected to a low temperature ageing treatment, at approximately to 480 °C (Known as H900 , as 900F is 480 °C) to obtained the sufficient strength. Cu-rich precipitates are formed at this ageing temperature increases the strength of the alloy. According to some product catalogues, after ageing the Mechanical properties developed will be T.S 1310 MPa, Y.S 1170 MPa with 8% elongation. As per reference technical online data sheet.

Composition of 17-4PH, SS 304L, ER 620 and ER 309 are listed in the Table 1

Table 1 Compositions, Wt.-% (Single value is max)

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo | Cu | Nb | N |

| 17-4PH | 0.04 | 0.4 | 0.02 | 0.005 | 0.5 | 15.0 – 17.5 | 3.0 – 5.0 | – | 3.5 | 0.15 – 0.45 | – |

| SS 304L | 0.03 | 2.0 | 0.04 | 0.03 | 0.75 | 18.0 – 20.0 | 8.00 – 12.0 | – | 0.2 | 0.10 | |

| ER 630 | 0.05 | 0.25 – 0.75 | 0.03 | 0.03 | 0.75 | 16.0 – 16.7 | 4.5 – 5.0 | 0.75 | 3.25 – 4.00 | 0.15 – 0.30 | |

| ER308L | 0.02 | – | 0.011 | 0.009 | 0.32 | 20 | 10.5 | – | 0.2 | 0.01 | 0.05 |

It is also recommended to do ageing after welding, even if the as welded properties are sufficient for design application. It is because, as-welded only (without ageing) contains untempered microstructure which may fail due to hydrogen embrittlement or stress corrosion crack in service.

17-4PH is a martensitic grade, while another grade of precipitation hardenable grade is 17-7PH in which, addition of slightly more Nickel is helping the retention of some austenite stable to room temperature so other grade 17-7PH is semi- austenitic type.

The matching filler metal of 17-4PH is ER 630 classified under AWS A5.9/A5.9M.

The 304L is an austenitic stainless steel, and the joint between 17-4PH & SS 304L is one of dissimilar metals. Here, at a first sight, we may prefer to choose ER 309L filler metal but the selection of filler metal also depends on the kind of heat treatment (ageing treatment being given to the weldments, looking at the technical data sheet, this alloys is also given H925, H1025, H1075, H1100 & also H1150 treatment to obtained the various mechanical properties requirement. So ER 309 is higher in alloy content compared to ER308L, which produces more ferrite in weld metal compared to ER308L , So if the weldment is to be heat treated at higher ageing temperature H100 and H1150, at this temperature range, the ferrite in weld metal may transform to sigma phase, which may cause weld embrittlement. So, filler metal producing lower ferrite content will be more preferred.

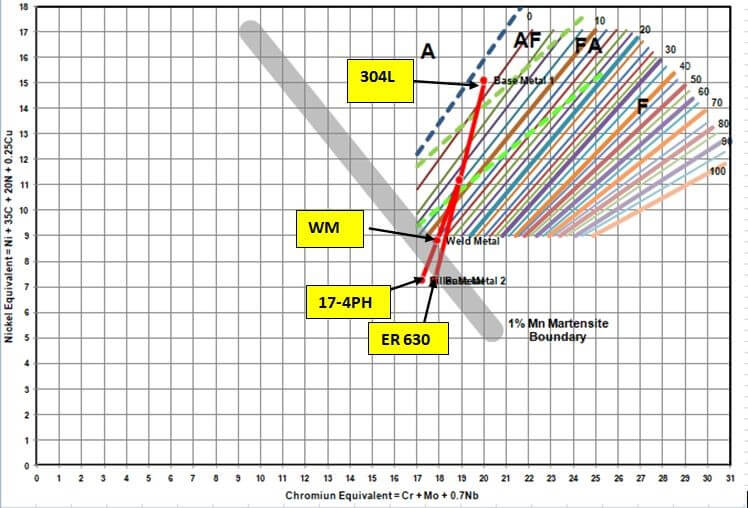

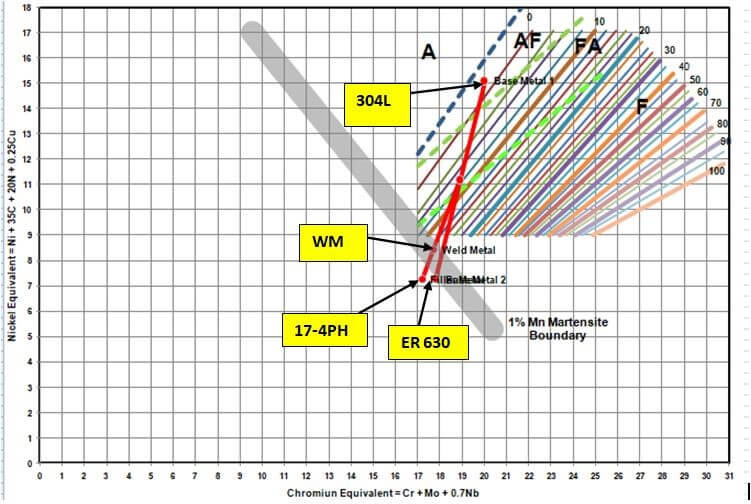

CASE- I : 17-4PH (BM 2) –SS 304L (BM 1) JOINT WITH ER 630 FILLER METAL. ASSUMED 40% DILUTION OF FILLER METAL.

CASE- II : 17-4PH (BM 2) –SS 304L (BM 1) JOINT WITH ER 630 FILLER METAL. ASSUMED 30% DILUTION OF FILLER.

When composition of the base metal 17-4PH Steel, SS 304L and filler metal ER 630 plotted on the WRC 1992 diagram indicates, it can be seen that 17-4PH and matching filler metal ER 630 being martensitic, their composition falls on 1% Mn martensitic Boundary while other base metal SS 304L being austenitic , its composition located on the top right inclined to approximately, 2 FN near AF boundary. Considering equal 15%-15% contribution from each base metals, i.e. total 30% dilution of filler metal , the weld metal composition is lying on martensitic boundary, which is not rather safe weld metal composition due to very poor weld metal ductility. Such weld metal have difficulty passing bend test. Besides this, such weld metal composition, depending on dilution of base metal into filler metal composition, may contain at least 15-20 FN , and rest of martensite which , during high ageing temperature may cause embrittlement in weldments by transformation of sigma phase from ferrite phase.

Now, as per figure 2. Considering 20% contribution from each base metal, i.e. total 40% dilution of filler metal, the resultant weld metal composition is falling inside to 1% martensitic boundary, that composition may or may not be brittle in nature. Because in GTAW, filler metal dilution may be varied from 30 to 40 % due to manual process. So, use of ER 630 filler metal for 17-4PH -304L dissimilar metal joint is not without a risk.

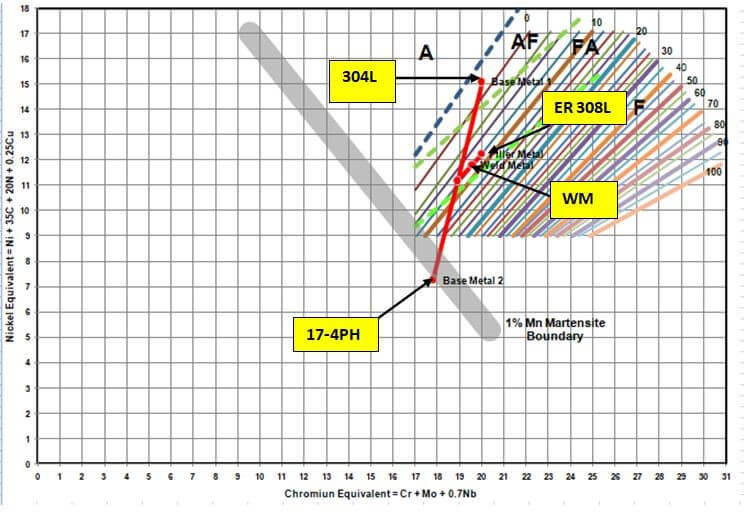

When similar exercise is done for 17-4PH, 304L and ER 308L filler metal. When compositions of each base metal and filler metal are plotted on WRC -1992 diagram. As can be seen in the figure 3, considering even 15 to 20% contributions from each base metal, i.e. at filler metal dilution level from 30 to 40% or even more, the weld metal composition will be austenitic, very ductile and safe from metallurgical point of view. Because it may contain approximately 8 FN and weld metal will undergo FA mode of solidification. So there will not be any risk of solidification cracking. Such a ductile weld metal contains very good mechanical properties and can easily pass bend test also. Moreover, less weld metal ferrite content, i.e. 8 FN poses very less possibility of converting in to sigma phase during ageing temperature, even if H1100 ageing treatment is required to be performed on weldments as said earlier. Various ageing treatment (at max temperature) can be done without any risk of embrittlement of weldments.

Moreover, ER 308L is easily available and cheaper in price than ER 630.

CASE- III : 17-4PH (BM 2) –SS 304L (BM 1) JOINT WITH ER 308L FILLER METAL . ASSUMED 30% DILUTION OF FILLER METAL.

We hope this information is useful to you!

Welding Consultant,

Weld Met Advisory Services

References:-

TECHNICAL DATA BLUE SHEET-

Stainless Steel AL 17-4™ Precipitation Hardening Alloy

http://www.specialtysteelsupply.com › brochure

Lippold JC, Kotecki DJ (2005) Welding metallurgy and weldability of stainless steels. Wiley Publication