INQUIRER:-

Dear Sir,

we have difficulty in meeting 40J CVN value in WM & HAZ at 0 degrees C. It is possible to achieve 40 J CVN value at 0 deg C test temperature in X50 micro-alloy steel with HF-ERW process?

in our process, Flat surface is going through roller and joint is made by the inductive heating coil.

We are obtaining ferrite on weld line slightly coarser than parent material ASTM No. 7 & while, on parent material ASTM grain Size No. 8-9 or finer. we know that actually ferrite is detrimental for lower temperature impact strength, we require 40 J at 0 degree Celsius. Herewith, I am providing microstructure of HF-ERW welded pipe weld line at 1000X magnification.

The microstructure of API X50 Material fabricated with HF-ERW process at 1000X

Answer

Dear Sir,

Generally, the pipelines used for the transportation of natural gas and oil can be manufactured using high-frequency electrical resistance welding

(HF-ERW), The nomial composition of API X60 grade material is as follow.

C 0.091, Si 0.171, Mn 1.061, P 0.08, S 0.003, Ti 0.020, V 0.004,

Nb 0.022, Cr 0.002, Ni 0.025, Cu 0.006, Al 0.047, N 0.004, Ca 0.002

Here the role of the Titanium & Niobium as micro alloys is to provide

heterogeneous nucleation site for promoting acicular ferrite production.

Bainitic strcture might help you meeting the impact strength requirement.

Looking at your HF-ERW pipe weld line microstructure, significant grain growth in WM and HAZ is observed which could be the possible root cause

of your problem.

I suggest you one of the latest research studies done by Gholamerza Khalaj et al, Microalloyed steel welds by HF-ERW technique: Novel PWHT cycles, microstructure evolution and mechanical properties enhancement (International Journal of Pressure Vessels and Piping · April 2017, DOI: 10.1016/j.ijpvp.2017.04.003.

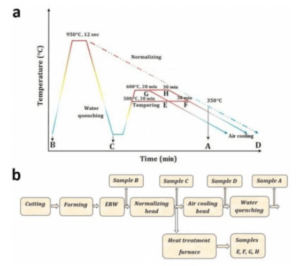

Gholamerza Khalaj et al examined results of grain size measurements and mechanical tests obtained from different eight specimens applied different PWHT cycles.

Their study reported CVN Value 39J at 0 C. for sample austenitized at 950 C for 12 Seconds, quenching in water and followed by tempering at 600 Deg temperature for 30 min time period.

in the above work, authors recommend that mechanical properties of one-step normalizing treatment satisfied the API specification, the two-step quenching, and tempering PWHTs were recommended for API X60 grade steels. authors also reported favoured uniform polygonal ferrite size of measured 5.3 and 5.4-micrometre size in the weld metal & HAZ microstructure respectively. Grain growth was also not reported during tempering because of the presence of micro-alloyed precipitates such as Nb (C, N) in steels.

Given as much as low heat input, grain growth can be reduced and you get the proper benefit of the best combination of strength & toughness.

With the Two-step tempering process, you can reduce ferrite grain size and better distribution of cementite in a microstructure that should resist crack propagation.

The below figure is captured from the said reference for you understand only. you may give it a try for your product. you might succeed in your work.

Proposed PWHT Cycle for API X60 [Source:-https://www.researchgate.net/publication/316344471]

Follow-up with the inquirer is continued.

We hope this information is useful to you!

Welding Consultant,

Weld Met Advisory Services

References:-

My LinkedIn Chat with the Welding Engineer Dtd. 3rd Oct 2020 onwards.

Gholamreza Khalaj, Hesam Pouraliakbar, Mohammad Reza Jandaghi, Abbas Gholami, “Microalloyed steel welds by HF-ERW technique: Novel PWHT cycles, microstructure

evolution and mechanical properties enhancement”, International Journal of Pressure Vessels and Piping · April 2017, DOI: 10.1016/j.ijpvp.2017.04.003.

https://www.researchgate.net/publication/316344471